We strictly control each process step, regardless of the stability of the product, the flatness of the surface treatment, the requirements of the fire rating, the guarantee of no harmful substances, the standards of sound insulation, etc., so let the world see our products from TAIWAN.

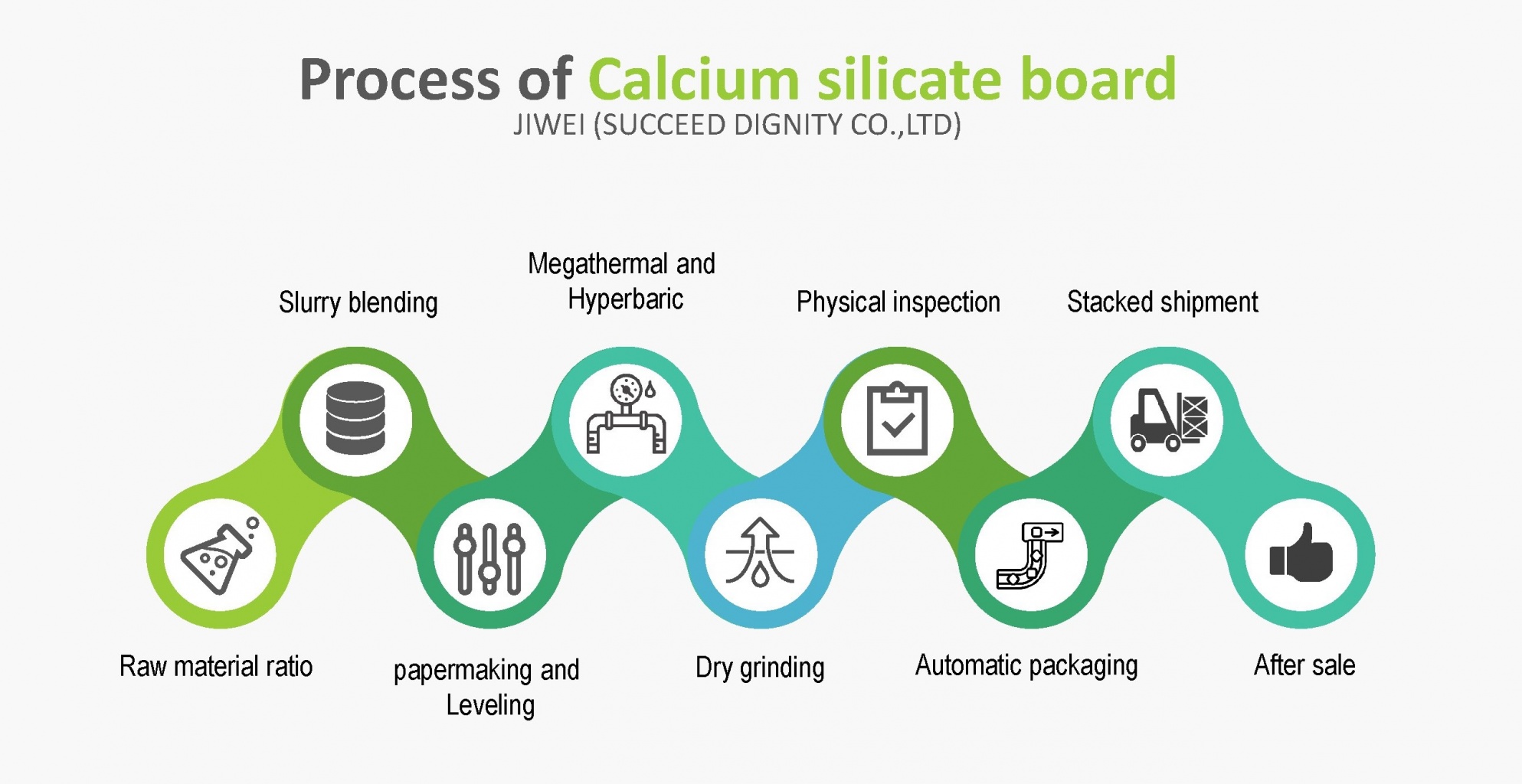

Step1 Raw material ratio

Specially selected imported high-quality tough heat-resistant fiber, plus silicon and calcium raw materials, cement and water, etc.

Step2 blending Slurry

Tough fibers and mineral raw materials are blended by fixed ratio and mixing uniformly.

The prepared raw materials are leveled by papermaking, then making into semi-finished products.

Step4 High-pressure steam curing

The semi-finished product into autoclave which is manufactured by steam curing for strengthening the plate structure of board.

Step5 Drying and polishing

By high temperature drying and surface polishing, the finished calcium silicate board becomes a high-quality building material with good smooth and stability.

Step6 Physical inspection

Finished product are checked quality by professional inspector.

Step7 Automatic packaging

Inspection of finished products are packaged automatically by machine.

Step8 Stacking and shipping

Use a load-bearing pallet so that problem of collapse doesn't occur during shipping.

Step9 After sale

JIWEI has a excellent reputation for business. our principle is Integrity of Business, responsible attitude is most important. Sincere and responsible is the most important in our principle.